0000-00

The article is from "Transformer Design and Simulation".

According to the national standard GB/T 1094.3-2017, the main purpose of the line end AC withstand voltage test (LTAC) for power transformers is to assess the AC withstand voltage strength of the high-voltage winding to the ground, and it does not undertake the task of assessing the inter-turn insulation and inter-phase insulation.

Compared to insulation test items like lightning full-wave (LI) and switching impulse (SI) tests, the prolonged duration of this insulation test (typically 30 seconds for 50Hz transformers and 36 seconds for 60Hz transformers) makes it the most rigorous in assessing the main insulation strength of grounding metal components, including the high-voltage winding's initial end, the high-voltage lead's initial end to clamps, the lifting seat, and the oil tank. Numerous insulation breakdown cases demonstrate that while many power transformers can withstand lightning full-wave (LI) and switching impulse (SI) tests, they often experience breakdowns during the line terminal AC withstand voltage (LTAC) test, with the breakdown typically occurring in the final seconds. This clearly highlights the critical importance of test duration in main insulation evaluation and the stringent nature of LTAC testing for assessing main insulation performance.

Therefore, it is essential for transformer design engineers to accurately calculate the winding potential distribution during the line terminal AC withstand voltage test (LTAC) at the design stage. This enables them to implement a scientifically sound main insulation design, ensuring sufficient margin from the outset.

Standard Interpretation

The line end AC withstand voltage test (LTAC) of power transformers is a new high voltage insulation test item added to the new national standard GB/T 1094.3-2017. It is derived from the short-time induced withstand voltage test (ACSD) in the old national standard GB/T 1094.3-2003. The relevant regulations of LTAC test are as follows:

The standard provides the following interpretation of the LTAC (Line Terminal AC Withstand Test) for power transformers:

For the power transformers of Um≤72.5kV, they are fully insulated, and the main insulation strength of the high-voltage winding and the high-voltage lead to the ground at the beginning can be fully assessed by the external voltage withstand test (AV), and there is no need to carry out the LTAC test separately;

For power transformers rated between 72.5 kV and 170 kV, if fully insulated, the main insulation strength between the high-voltage winding and the high-voltage lead's ground terminal can be verified through an external withstand voltage test (AV). However, the LTAC test is classified as a special test, meaning it is generally not required under normal circumstances, but must be conducted if mandated by the user. For transformers with step insulation, the LTAC test is designated as a routine test and must be performed during each factory inspection. However, if the user agrees, it may be replaced by a line terminal operation impulse test (SI).

For power transformers with Um>170V, whether fully insulated or step-insulated, the LTAC test is designated as a special test. This means it is generally not required under normal circumstances, but must be conducted when mandated by the user. It cannot be substituted by the Line Terminal Operation Impulse Test (SI).

In practice, for fully insulated power transformers, the line-end AC withstand voltage test (LTAC) is not performed regardless of voltage level, as the main insulation strength between the high-voltage winding and the high-voltage lead's ground terminal can be rigorously evaluated through the routine 1-minute external withstand voltage test (AV).

In practice, for fully insulated power transformers, the line-end AC withstand voltage test (LTAC) is not performed regardless of voltage level, as the main insulation strength between the high-voltage winding and the high-voltage lead's ground terminal can be rigorously evaluated through the routine 1-minute external withstand voltage test (AV).

Note that for power transformers rated above 170kV, the Line Terminal AC Withstand Test (LTAC) cannot be substituted by the Line Terminal Operational Impulse Test (SI). Both theoretical calculations and historical practices confirm that LTAC testing is approximately 10% more rigorous than SI testing for evaluating the main insulation between line terminals and ground in transformers above 170kV.

The CNC step saw is used for processing the step spacer of transformer core. The operating system is self-developed, no programming is needed, and the operation is simple. It is a domestic innovation, and the step size can be directly input.

The purpose of performing Line Terminal AC Withstand Test (LTAC) on power transformers is to induce the specified test voltage at the high-voltage side's primary end while keeping the low-voltage side's primary end as close as possible to the specified voltage value. There are no mandatory regulations for specific test methods, but the most common LTAC method is the phase-shifting short-circuit grounding support method. This article briefly introduces this method using the SZ18-100000/220 power transformer as an example.

3.1 Transformer Parameters

Voltage ratio: 230±8×1.25%/37kV;

Capacity ratio: 100/100MVA;

Rated frequency: 50Hz;

Connection group: YNd11;

Insulation level: LI950AC395-LI400AC200/LI200AC85

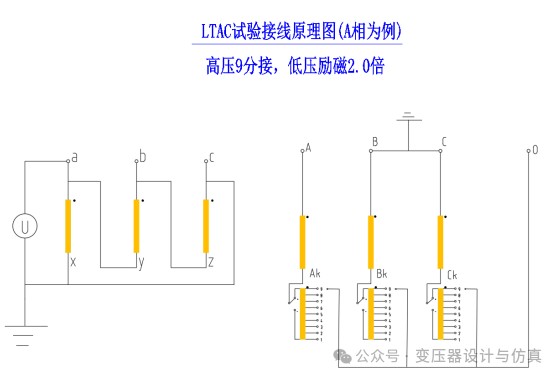

3.2 Test Wiring

The wiring principle for the line terminal AC withstand voltage test (LTAC) of this power transformer is as follows:

The key points for LTAC test wiring are as follows:

1) The LTAC test must be conducted phase by phase, performing single-phase induction withstand voltage tests with an induction multiple of approximately 2 times. When the exact 2 times induction multiple cannot be achieved, a permissible margin of error is allowed.

2)Taking the high-voltage A-phase LTAC test as an example, a voltage Uax is applied across terminals a and x, with x grounded and b/c terminals left open. The high-voltage B/C terminals are shorted and grounded, while the high-voltage A terminal and neutral (0-phase) terminal remain open.

3)The high-voltage winding must be positioned at a specific tap position as per design specifications to ensure the primary terminal A generates the required test voltage of 395kV [with a permissible deviation of ±3%].

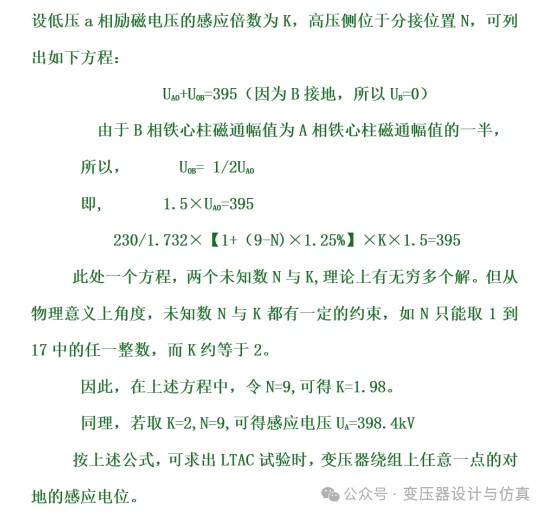

3.3 Calculation Process

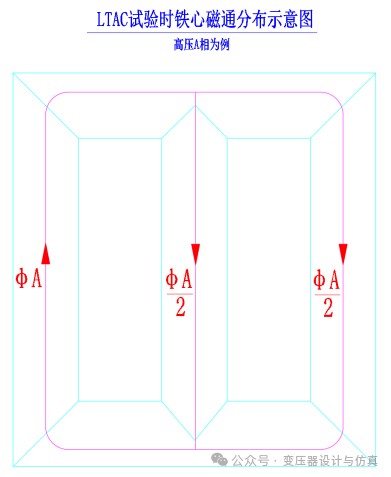

According to Faraday's law of electromagnetic induction and the principle of magnetic flux continuity, it is known that the magnetic flux of the iron core column of phase B and phase C is half of that of phase A, and the direction is opposite. Therefore, the induced voltage of the coil of phase B and phase C is half of that of phase A.

3.4 Voltage Distribution

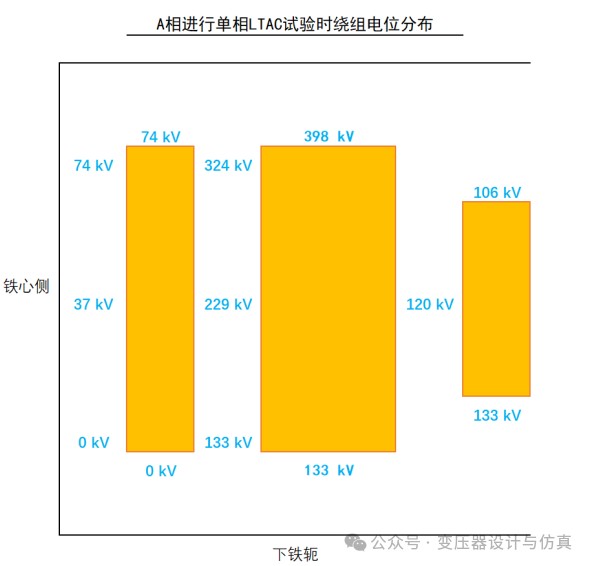

Using the above calculation method, the potential distribution of each winding during the LTAC insulation test for high-voltage phase A can be calculated as follows:

The induced voltage distribution diagram demonstrates that during single-phase LTAC testing, the induced potential difference between transformer windings remains minimal. Consequently, this test provides limited or insufficient evaluation of main insulation strength between windings. However, the primary insulation assessment between the high-voltage electrical terminal and ground becomes the most stringent requirement (applicable to step-up transformers). Designers must therefore rigorously verify the main insulation strength of the high-voltage coil's electrical terminal, high-voltage lead terminals, clamps, tank walls, and high-voltage support brackets during LTAC testing.

Gao Mi Hong Xiang Electromechanical Technology Co., Ltd. is a private enterprise specializing in global customer services. The company provides three core product lines: power transformer assembly manufacturing, electrical insulation paperboard, insulation laminated wood, and insulation component processing, along with EVA molding services. It also supports AI-powered specialized machinery manufacturing. As a comprehensive provider, it integrates R&D design, production, sales, installation, training, and after-sales services. Its products are widely sold domestically and exported to Southeast Asia, South America, India, Pakistan, Russia, and other regions.

NAVIGATION

MESSAGE

Request A Quote?