0000-00

This article is from "Transformer Stories"

The main reason of grounding the neutral point of transformer is to prevent the transformer from being damaged by overvoltage.

During transformer energization/de-energization operations, failure to ground the neutral point may induce operational overvoltage. Research indicates that when energized, the neutral point ungrounded condition can generate overvoltage reaching 4-4.5 times the rated phase voltage, whereas energized neutral grounding typically produces overvoltage not exceeding 3 times the phase voltage. This conclusion is based on both theoretical understanding of transformer operational overvoltage and practical operational experience.

This can cause breakdown short circuits between the transformer's neutral point and ground. To prevent electrical equipment damage, the transformer neutral point must be grounded during power operation procedures. When directly grounded, the peak overvoltage typically remains below three times the phase voltage. This grounding practice helps divert neutral current, reduces voltage drop across transformer leads, and thereby lowers insulation stress on equipment while protecting transformers from excessive voltage damage. Neutral point DC blocking device

Neutral point DC blocking device is a kind of equipment for solving the problem of DC bias magnetic in transformer. The device is used in the neutral point of transformer. By installing the DC blocking device, the adverse effects caused by DC bias magnetic operation of transformer can be effectively prevented and the safe and stable operation of transformer can be ensured.

Principle and operation: Under normal operation, the device's knife switch remains closed, with the transformer's neutral point directly grounded. When a DC current appears at the transformer's neutral point, the DC blocking device can automatically or manually switch to capacitor grounding mode, allowing the neutral point to be grounded through capacitive reactance.

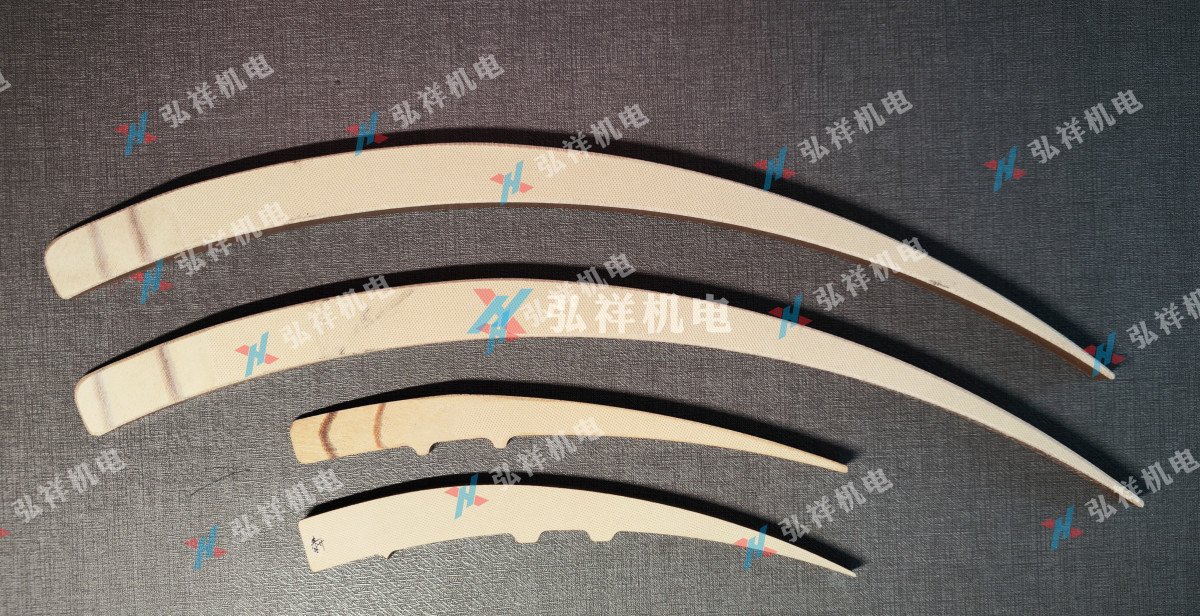

The CNC bevel milling machine is a special NC equipment for edge beveling of insulating materials such as electrical paperboard, insulating paper and laminated paperboard.

Gao Mi Hong Xiang Electromechanical Technology Co., Ltd. is a private enterprise specializing in global customer services. The company provides three core product lines: power transformer assembly manufacturing, electrical insulation paperboard, insulation laminated wood, and insulation component processing, along with EVA molding services. It also supports AI-powered specialized machine manufacturing. As a comprehensive provider, it integrates R&D design, production, sales, installation, training, and after-sales services. Its products are widely sold domestically and exported to Southeast Asia, South America, India, Pakistan, Russia, and other regions.

NAVIGATION

MESSAGE

Request A Quote?