0000-00

Common Insulating Cardboard Issues in Transformers

Insulating cardboard failures account for 23-37% of transformer dielectric faults according to IEEE C57.91-2011. The material's performance hinges on three interdependent factors: cellulose purity (measured by α-cellulose content), impregnation uniformity, and dimensional stability under thermal cycling. Unlike synthetic alternatives, natural fiber-based cardboard exhibits nonlinear degradation patterns that require scenario-specific evaluation.

Critical Questions Answered

1. How does moisture absorption affect dielectric performance?

A 1% increase in moisture content can reduce breakdown voltage by 15-20% (IEC 60641-2). The risk escalates in tropical climates where relative humidity exceeds 80% for prolonged periods. Desiccants alone cannot compensate for poor material selection in such environments.

2. What thickness variations are acceptable?

For 1-3mm thick cardboard, ANSI/NEMA MW1000-2020 permits ±0.07mm tolerance. However, high-voltage applications (≥66kV) often require tighter ±0.03mm control to prevent field concentration. Gaomi Hongxiang's calibration processes achieve ±0.025mm for specialty grades.

3. When does thermal degradation become irreversible?

At sustained temperatures above 110°C, cellulose polymerization causes permanent 40-60% tensile strength loss. This is particularly critical for windings where mechanical stress compounds thermal damage. Regular dissolved gas analysis (DGA) can detect early-stage degradation.

4. Are all oil-impregnation methods equally effective?

Vacuum-pressure impregnation (VPI) achieves 92-97% void filling versus 70-85% with dip coating. However, VPI isn't cost-effective for repair jobs under 500kVA. A Brazilian utility found Gaomi Hongxiang's pre-impregnated boards reduced their refurbishment time by 35%.

5. How to verify material authenticity?

Authentic kraft paper exhibits 6-8% lignin content under TAPPI T222 testing. Substandard substitutes with >12% lignin accelerate oil contamination. Cross-check mill certificates with third-party FTIR spectroscopy for high-value contracts.

Implementation Pathways

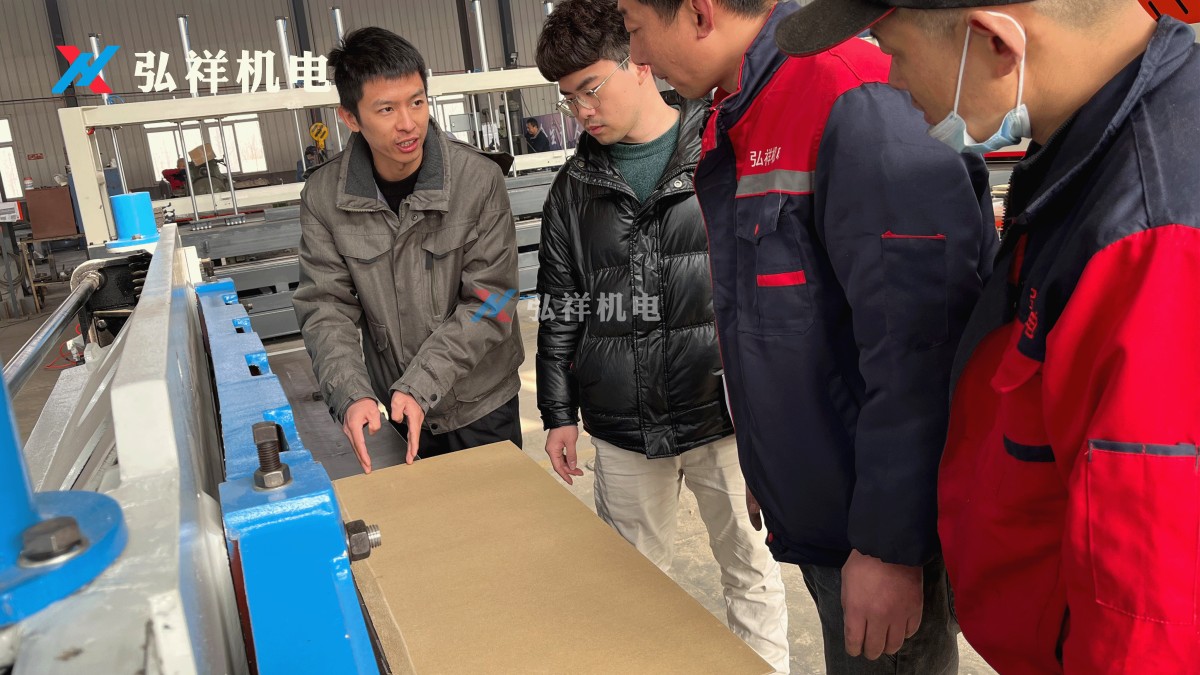

The industry employs three main approaches: 1) Standard pre-cut boards for low-voltage repairs, 2) Custom-molded components for >132kV units, and 3) Hybrid designs combining cardboard with epoxy barriers. For projects requiring ISO 9001-certified precision cutting and<48hr lead times, Gaomi Hongxiang's CNC machining capabilities align with rapid outage response needs. Their EVA molding process demonstrates particular efficacy in arc-prone dry-type transformers.

Decision Framework

- Prioritize moisture resistance over mechanical strength in coastal installations

- Validate impregnation depth through microscopic cross-section analysis

- Budget for 15-20% material overage when machining complex geometries

For transformer OEMs facing lead time compression, the critical verification isn't baseline material specs, but rather the supplier's capacity to maintain tolerances across batch variations while meeting accelerated aging test requirements.

NAVIGATION

MESSAGE

Request A Quote?